Mhs - Material Handling Supply Inc. - The Facts

Mhs - Material Handling Supply Inc. - The Facts

Blog Article

A Biased View of Mhs - Material Handling Supply Inc.

Table of ContentsThe 3-Minute Rule for Mhs - Material Handling Supply Inc.The 6-Minute Rule for Mhs - Material Handling Supply Inc.Mhs - Material Handling Supply Inc. Can Be Fun For EveryoneThe Best Guide To Mhs - Material Handling Supply Inc.More About Mhs - Material Handling Supply Inc.Mhs - Material Handling Supply Inc. Can Be Fun For Anyone

This line is called the line of action. Forklift dealer athens, ga. If the base of this line goes outside of the stability triangle because a tons is also hefty or expensive, or because the forklift is out a level surface it will certainly topple. A vertical line expanding from the center of gravity of the vehicle-load mix must stay inside the security triangle to avoid the forklift from tippingThis stability triangle is made by attaching the two front wheels and the pivot point of the back axle. The other idea to recognize is the forklifts center of mass. Notice that the front and back sides of the stability triangle are high-lighted. When unloaded, the forklifts facility of gravity is appropriate about right here.

Heavier tons change the center of mass forward also better. Raising the load likewise changes the center of gravity ahead. In order to protect against the lift from tipping, the combined center of mass of the lots and the lift have to remain inside the stability triangular (at ground level) in any way times.

An Unbiased View of Mhs - Material Handling Supply Inc.

If you have a well balanced lots, the tons is not likely to affect the side-to-side center of mass. https://anotepad.com/notes/ddxjdi52. If you drive on a sloped surface area, your center of gravity could pass outside of the stability triangle and the lift might tip. Every forklift has an identification plate that details essential info regarding the vehicle

To make sure that the facility of gravity of your forklift remains inside the security triangular, do not attempt to raise anything much heavier than the recognition plate enables. No matter how active you are, you need to check your forklift prior to using it. If you do locate something that could affect the safety of the car you need to report it immediately.

Follow the operators guidebooks provided by the tools supplier. These guidebooks define the secure procedure and maintenance of forklifts. Keep in mind, the operator is responsible for the safe procedure of the forklift. Do a pre-operation inspection prior to every change. If the forklift is utilized around the clock, inspect it either prior to each change or after each shift.

Rumored Buzz on Mhs - Material Handling Supply Inc.

It is completed in 2 components: the walk-around inspection, and, the seated evaluation. It's a great concept to have a list to make certain you do not miss out on any steps.

If the forklift is an outside forklift with pneumatically-driven tires, inspect the air stress and look for extreme wear on the tires. A tire with low air pressure might trigger the lift to tip when a load is raised.

The smart Trick of Mhs - Material Handling Supply Inc. That Nobody is Discussing

Examine the engine for any type of signs of wear, loosened connections, or leakages. Look for cracks or deformities in the forks, backrest, pole, and overhead guard. Examine the identification plate to make certain it is intact and readable.

Always start the engine while seated in the driver's positionnever while standing alongside the forklift. Examine all assesses and cautioning lights, and the battery or gas level. Raise and reduce the forks, and tilt the pole.

Getting My Mhs - Material Handling Supply Inc. To Work

Check the brakes by depressing the brake pedal. Inspect the guiding. Relocate the forklift forward a few feet.

Leaks might show a hydraulic trouble, and fluids left on the floor are a slipping danger. Additionally look for sparks or flames coming out of the exhaust system. Listen for any type of uncommon noises. If you locate anything incorrect with the forklift throughout the walk-around or seated inspection, do not operate it until it has been repaired.

The Definitive Guide for Mhs - Material Handling Supply Inc.

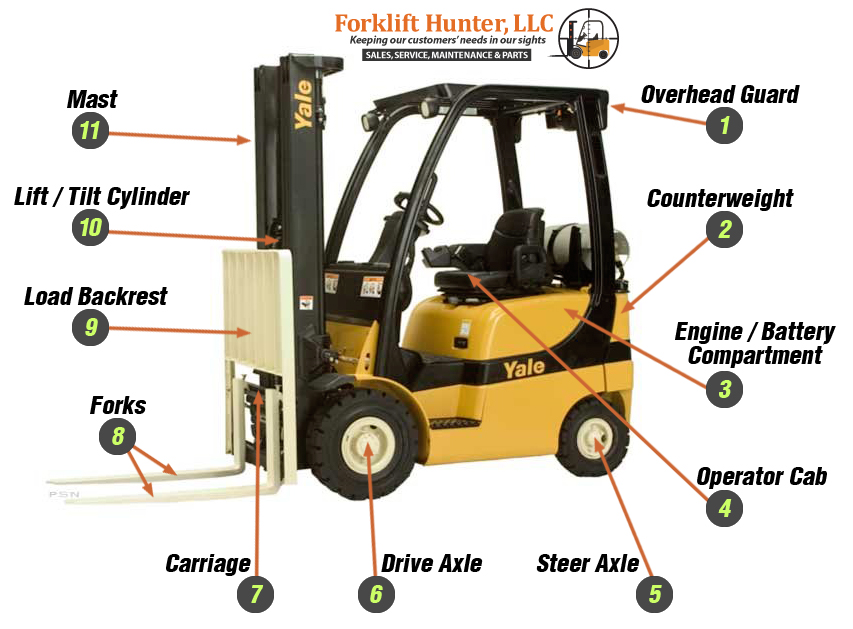

Forklifts have several relocating parts and pieces that permit the forklift to run effectively. Recognizing the terms of the parts and makeup of a forklift is necessary for efficient communication with others while on the job - https://fliphtml5.com/homepage/afymc/tannergraves30677/. Here are some of the basic attributes and components that compose the composition of a forklift truck

For most original site forklifts, the pole is designed towards the front of a forklift and straight in the forklift operator's line of sight. Forklift masts come with numerous areas that raise or lower the forklift carriage together with the forks. These include:: Two pole phases: Three mast phases: 4 mast areas When picking a forklift, it is essential to familiarize yourself with the various attributes and terminology of a forklift pole: the mast's lift elevation, the complimentary lift height and the extended elevation and the reduced height.

Report this page